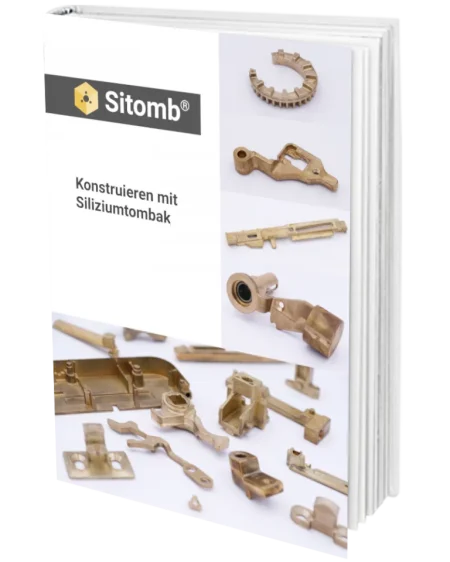

Until now, we only knew the manufacturing processes of investment casting and MIM for high-strength and high-precision structural parts. However, die casting from Sitomb is a real alternative.

Customer from the locking technology sector

You are currently viewing a placeholder content from YouTube. To access the actual content, click the button below. Please note that doing so will share data with third-party providers.

More InformationYou are currently viewing a placeholder content from YouTube. To access the actual content, click the button below. Please note that doing so will share data with third-party providers.

More Information

Until now, we only knew the manufacturing processes of investment casting and MIM for high-strength and high-precision structural parts. However, die casting from Sitomb is a real alternative.

Customer from the locking technology sector

In our case, the investment in the die casting tool paid for itself after 16 months.

Customer from the automotive industry

Our MIM parts had to be coated for corrosion protection. Corrosion and coating is no longer an issue for us due to conversion to Sitomb.

Customer from the medical technology sector

Enormous savings potential compared with components made of steel investment castings.

Customer from the fittings industry

You need to load content from reCAPTCHA to submit the form. Please note that doing so will share data with third-party providers.

More Information